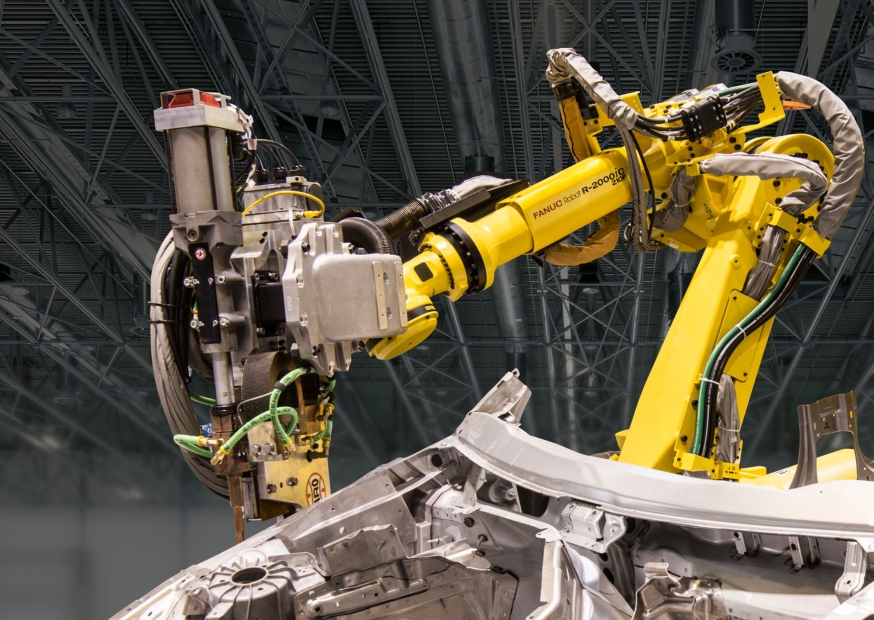

Robotic arms, at the core of modern manufacturing and production have been transforming the norms in a way that was previously unimaginable. They bring high-quality, safety and efficacy. These marvels of the mechanical realm – sometimes called robot arms become indispensable to businesses all over the world, motivated by the need to cut operating costs without sacrificing quality. Incorporating robotic arms into the production lines allows manufacturers to reduce their costs, but also increase work safety and efficiency. Let’s examine how these groundbreaking machines are reshaping the landscape of industrial production.

Image credit: automatedsolutions.com.au

The primary force behind the global surge in robotic arm adoption is cost efficiency. Factory owners are constantly under pressure to minimize workplace injuries, minimize manufacturing errors, and decrease the amount of waste. Robotic arms are specifically designed to tackle these problems. In contrast to human workers, robotic arms complete repetitive tasks with pinpoint precision to avoid costly mistakes and reducing the waste of raw material. Robotic arms are utilized in high-volume industries for example, the automobile industry, in order to ensure flawless assembly. This can lead to substantial savings, as fewer defective parts means less rework and waste.

Safety is another important aspect of the robotic arm revolution. Certain manufacturing processes like handling dangerous materials or using heavy machinery can be dangerous to human workers. By utilizing robot arms enterprises can take workers away from hazardous environments. This minimizes the possibility of injury at work. Robotic arms are comprised from a set of moveable joints that mimic the human arm’s function. But, they work without danger of injuries. Equipped with programmable end effects basically robotic hands, These machines are able to perform tasks like grasping, spinning, or welding in conditions that would be unsafe for humans.

Robot arms’ versatility is a game-changer in many industries. From assembly for automobiles to electronic production, robots can adapt to a variety of tasks. The programmability of these robot arms allows them to execute complex tasks like painting or applying fiberglass with an unmatched level of consistency. Robotic arms in warehouses have revolutionized palletizing by automating process of loading products onto pallets. The automation improves productivity as well as reliability because robot arms work constantly without fatigue.

The rise of cobots (collaborative robots) that interact with human workers is one of the most exciting developments in this area. Contrary to traditional industrial robots which are restricted to isolated cells. Cobots fitted with robotic arms have been designed to ensure safe and seamless interactions with humans. The hands of a robot is able to do difficult lifting tasks and repetitive tasks in factories, which means humans are freed to perform more demanding tasks. The collaboration improves efficiency and ensures a secure workplace, since cobots can be programmed to change or stop their movements when someone is nearby.

Robotic arms have a significant influence on the modern production, and not only regarding safety or efficiency. The ability robotic arms to carry out tasks that require precision, such as welding, material handling, or assembly have made them indispensable in areas that place safety first. In the production of automobiles for instance, a robot arm can move and position components during assembly for perfect alignment without the need for human involvement. In the field of electronics, robots can be used to handle delicate components, which reduces damage and improves output quality.

As the world of manufacturing continues to change with the advancement of technology, the need for robotic arms will continue to grow. Their capacity to cut costs, enhance safety, and adjust to different jobs makes them an integral part of manufacturing’s future. By combining cutting-edge technology with human creativity robot arms aren’t just tools they’re partners in progress, driving innovation and transforming the way we create our world.